Textile tracers: a promising innovation

What is the K-loop project?

The fabrics used to make K-loop bags come from recovering production scrap from Kariban Brand products. The aim of the project is to sort and recycle production scrap from our production factories.

We collect all the bundles of scrap material (which we refer to as "Jhoot") and transport them to the spinning centre 20 km from our production factories. This proximity means that we can also minimise our carbon footprint.

In the "Symco" spinning mill, the fabrics are separated by colour whenever possible. If there are insufficient scraps, the fabrics are all mixed together regardless of colour, which can give the finished product a mottled appearance. Once the colours have been separated, everything is shredded to create a cotton amalgam that can then be trimmed.

Yarn processed in this way is too short to be spun on its own, so we add polyester fibres (from recycled PET water bottles) during spinning.

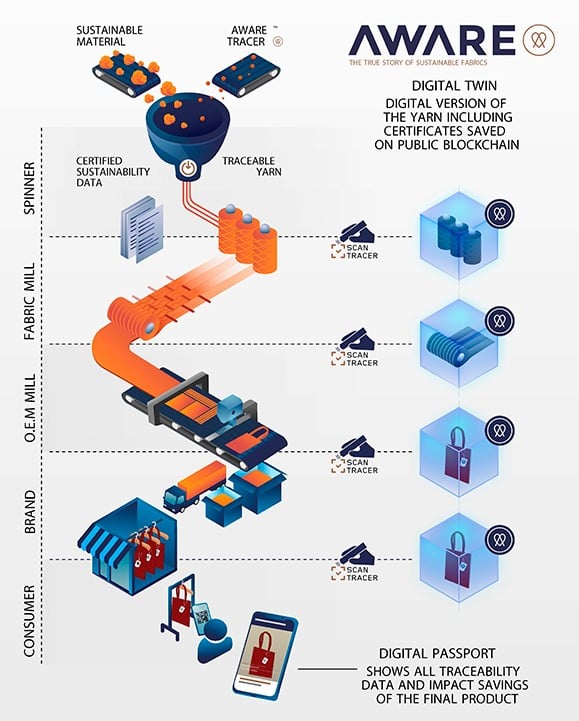

During this process, we also add Aware™ tracers to track the origin of all the recycled materials through information recorded in a blockchain.

Once the yarn is obtained, we transfer it to our partner Ausbanglatex who take care of everything else i.e. weaving the canvas, cutting it and sewing it into the bags you have in your hands.

For every K-loop product we can certify the water and energy savings we have made by recycling our cotton.

What are Aware™ tracers?

Using the combination of the Aware™ programme and blockchains we can trace, measure and certify each step in the process. When we spin our cotton, we incorporate tracers (ceramic microparticles) which will identify the material right from the beginning of the process.

At each step in the manufacture, our partners store the data in a "unique digital passport" (the notorious tokens). These tokens are then stored in a decentralised blockchain. This ensures that this data is always unique, truthful and cannot be modified throughout the production process, right through to the end customer. Not only is the fabric traceable, but every time it is turned into a product it can always be traced back to the origin of the recycled material.

Digital technology serving the textile industry - this is a further step towards a sustainable future and a guarantee of total transparency for the end customer.

The K-Loop project by Kimood and K-up

Kimood and K-up, our specialist luggage and headwear brands, have come together to develop the K-loop project; part of an approach focusing on the environment and traceability.